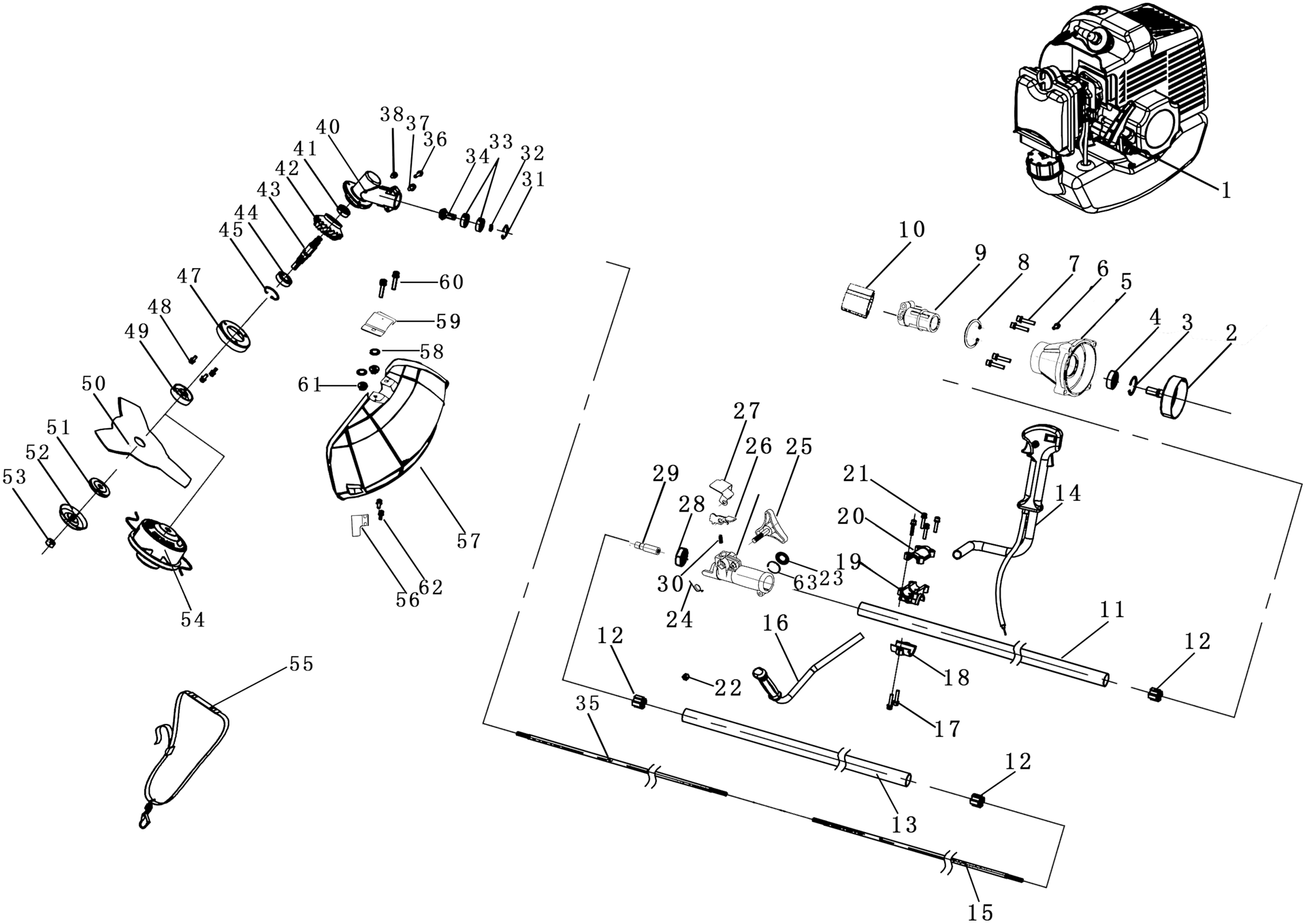

Brush Cutter Accessories

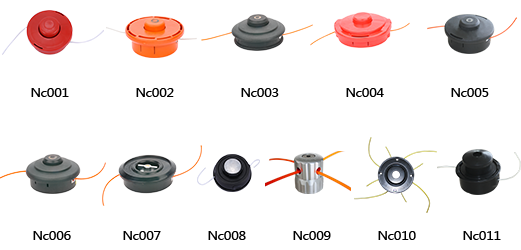

Trimmer Head

Trimmer Head

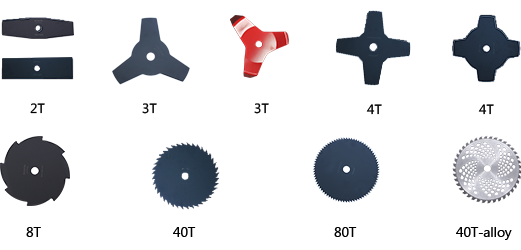

Blade

Blade

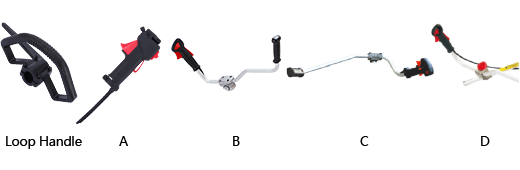

Handle for brush cutter

Handle for brush cutter

Belt

Belt

Guards

Guards

Safety Kts

Safety Kts

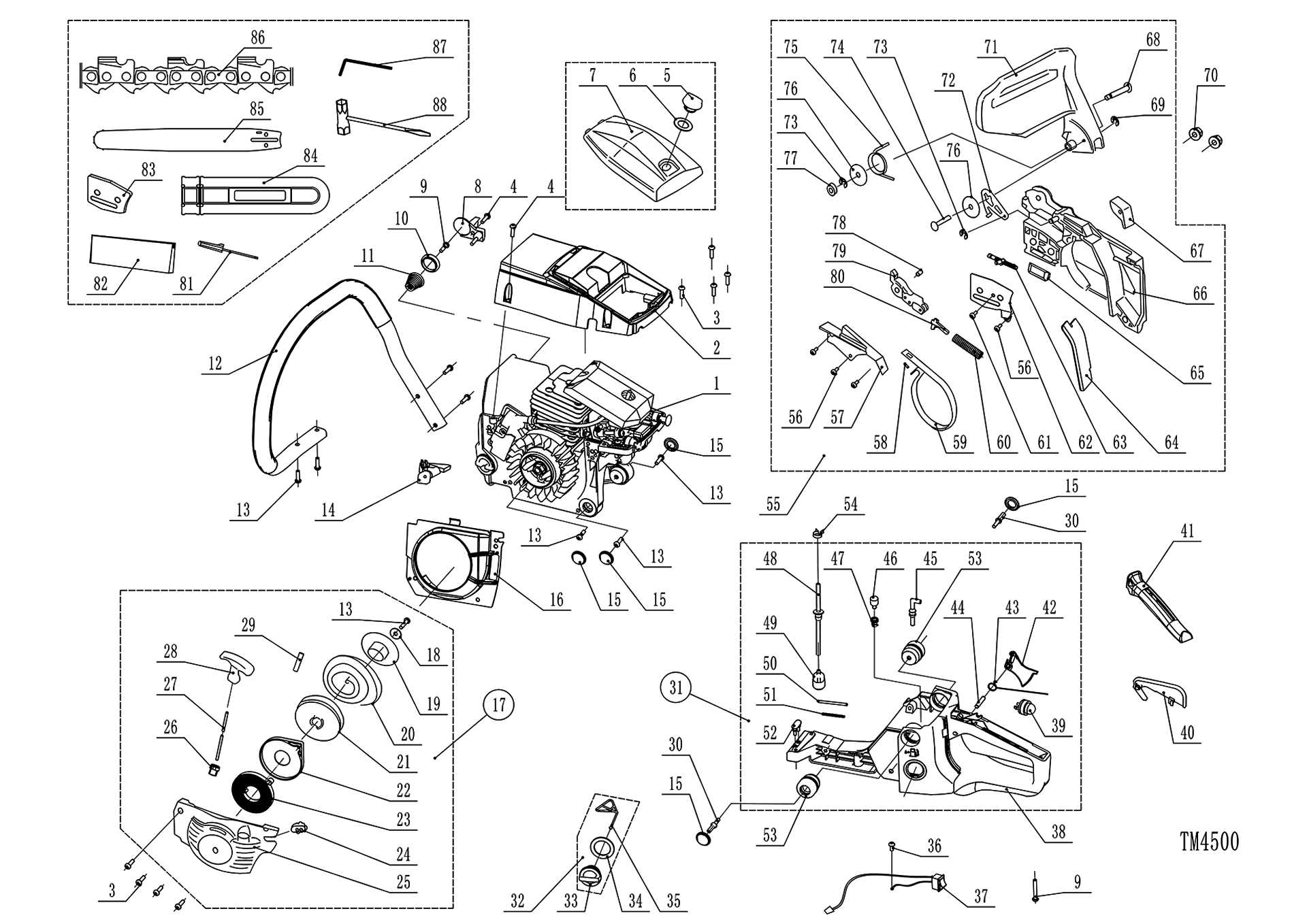

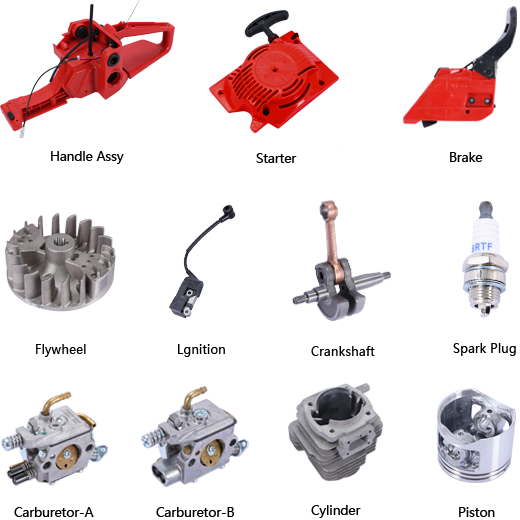

Chainsaw Accessories

Chainsaw Accessories

Chainsaw Accessories

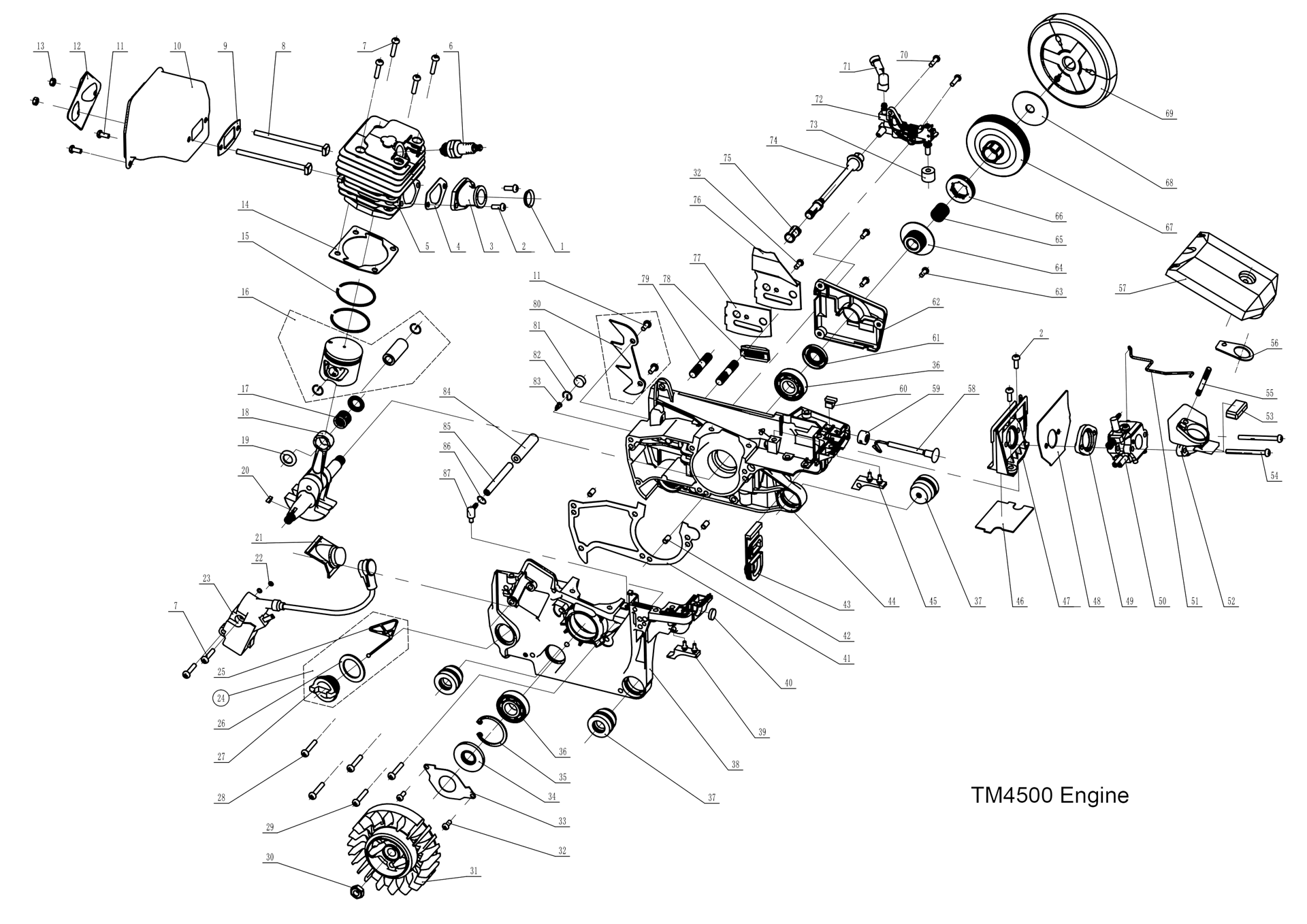

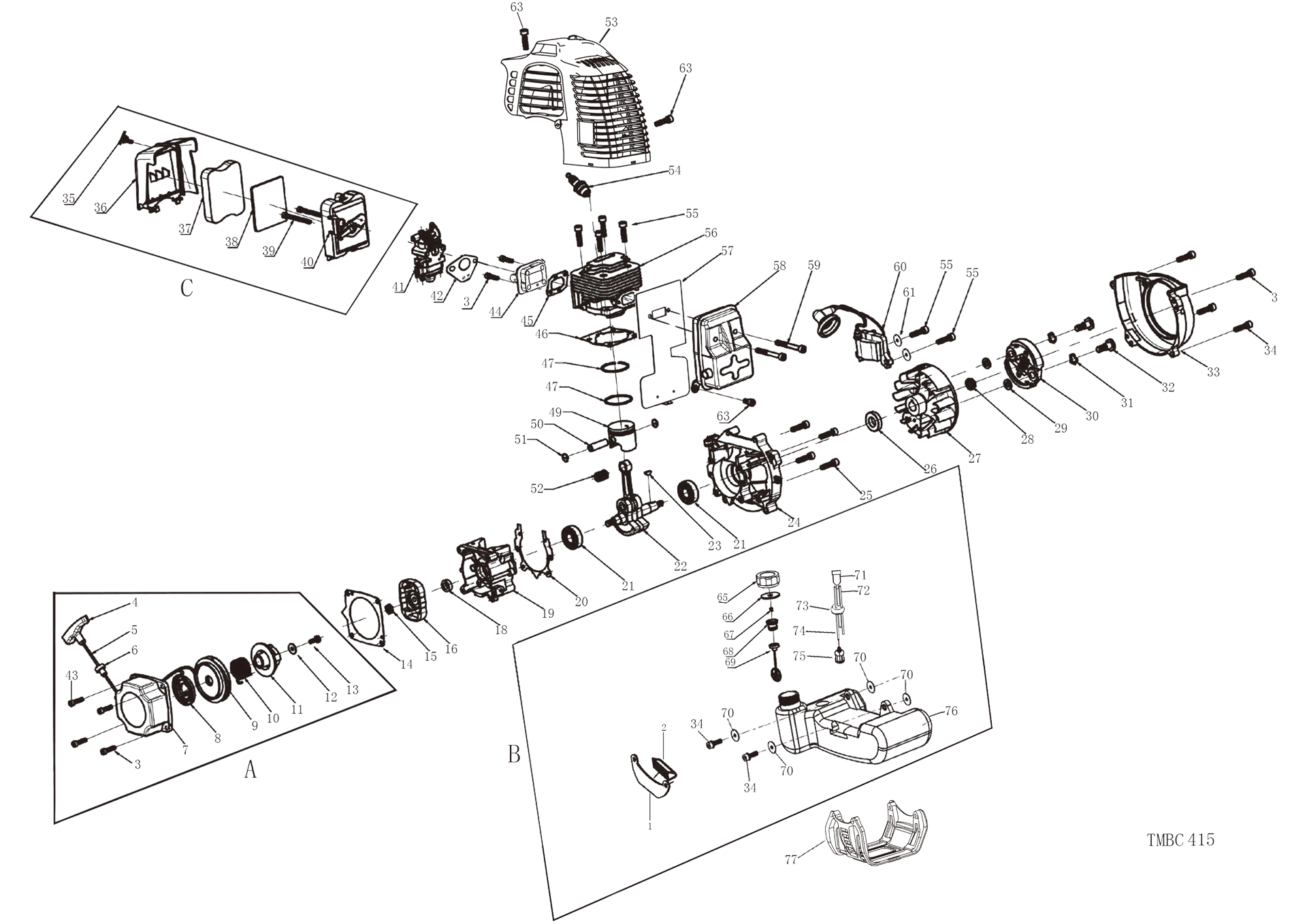

Spare Parts

Spare Parts

Frequently Asked Questions(FAQ)

1. Never operate a chain saw when you are fatigued, ill, or upset, or under the influence of medication that may make you drowsy, or if you are under the influence of alcohol or drugs.

2. Use safety footwear, snug fitting clothing and eye, hearing and head protection devices.

3. Always use caution when handling fuel. Wipe up all spills and then move the chain saw at least ten(10) feet(three(3) m) from the fueling point before starting the engine.

(3a) Eliminate all sources of sparks or flame (ie. smoking, open flames, or work that can cause sparks) in the areas where fuel is mixed, poured, or stored.

(3b)Do not smoke while handling fuel or while operating the chain saw.

4. Do not allow other persons to be near the chain saw when starting the engine or cutting a wood. Keep bystanders and animals out of the work area. Children, pets, and bystanders should be a minimum of thirty(30) feet away when you start or operate the chain saw.

5. Never start cutting until you have a clear work area, secure footing, and planned retreat path from the falling tree.

6. Always hold the chain saw firmly with both hands when the engine is running. Use a firm grip with thumb and fingers encircling the chain saw handles.

7. Keep all parts of your body away from the saw chain when the engine is running.

8. Before you start the engine, make sure the saw chain is not contacting anything.

9. Always carry the chain saw with the engine stopped, the guide bar and saw chain to the rear, and the muffler away from your body.

10. Always inspect the chain saw before each use for worn, Ioose, or changed parts. Never operate a chain saw that is damaged, improperly adjusted, or is not completely and securely assembled. Be sure that the saw chain stops moving when the throttle control trigger is released.

11. All chain saw service, other than the items listed in the Operator’s Manual, should be performed by competent chain saw service personnel. (e.g., if improper tools are used to remove the flywheel, or if an improper tool is used to hold the flywheel in order to remove the clutch, structural damage to the flywheel could occur which could subsequently cause the flywheel to disintegrate).

12. Always shut off the engine before setting it down.

13. Use extreme caution when cutting small size brush and saplings because slender material may catch the saw chain and be whipped toward you or pull you off balance.

14. When cutting a limb that is under tension, be alert for spring back so that you will not be struck when the tension in the wood fibers is released.

15. Keep the handles dry, clean and free of oil or fuel mixture.

16. Operate the chain saw only in well ventilated areas. Never start or run the engine inside a closed room or building. Exhaust fumes contain dangerous carbon monoxide.

17. Do not operate a chain saw in a tree unless specially trained to do so.

18. Guard against kickback. Kickback is the upward motion of the guide bar which occurs when the saw chain at the nose of the guide bar contacts an object. Kickback can lead to dangerous loss of control of the chain saw.

2. Use safety footwear, snug fitting clothing and eye, hearing and head protection devices.

3. Always use caution when handling fuel. Wipe up all spills and then move the chain saw at least ten(10) feet(three(3) m) from the fueling point before starting the engine.

(3a) Eliminate all sources of sparks or flame (ie. smoking, open flames, or work that can cause sparks) in the areas where fuel is mixed, poured, or stored.

(3b)Do not smoke while handling fuel or while operating the chain saw.

4. Do not allow other persons to be near the chain saw when starting the engine or cutting a wood. Keep bystanders and animals out of the work area. Children, pets, and bystanders should be a minimum of thirty(30) feet away when you start or operate the chain saw.

5. Never start cutting until you have a clear work area, secure footing, and planned retreat path from the falling tree.

6. Always hold the chain saw firmly with both hands when the engine is running. Use a firm grip with thumb and fingers encircling the chain saw handles.

7. Keep all parts of your body away from the saw chain when the engine is running.

8. Before you start the engine, make sure the saw chain is not contacting anything.

9. Always carry the chain saw with the engine stopped, the guide bar and saw chain to the rear, and the muffler away from your body.

10. Always inspect the chain saw before each use for worn, Ioose, or changed parts. Never operate a chain saw that is damaged, improperly adjusted, or is not completely and securely assembled. Be sure that the saw chain stops moving when the throttle control trigger is released.

11. All chain saw service, other than the items listed in the Operator’s Manual, should be performed by competent chain saw service personnel. (e.g., if improper tools are used to remove the flywheel, or if an improper tool is used to hold the flywheel in order to remove the clutch, structural damage to the flywheel could occur which could subsequently cause the flywheel to disintegrate).

12. Always shut off the engine before setting it down.

13. Use extreme caution when cutting small size brush and saplings because slender material may catch the saw chain and be whipped toward you or pull you off balance.

14. When cutting a limb that is under tension, be alert for spring back so that you will not be struck when the tension in the wood fibers is released.

15. Keep the handles dry, clean and free of oil or fuel mixture.

16. Operate the chain saw only in well ventilated areas. Never start or run the engine inside a closed room or building. Exhaust fumes contain dangerous carbon monoxide.

17. Do not operate a chain saw in a tree unless specially trained to do so.

18. Guard against kickback. Kickback is the upward motion of the guide bar which occurs when the saw chain at the nose of the guide bar contacts an object. Kickback can lead to dangerous loss of control of the chain saw.

Kickback may occur when the nose or tip of the guide bar touches an object, or when the wood closes in and pinches the saw chain in the cut. Tip contact in some cases may cause a lightning fast reverse reaction, kicking the guide bar up and back towards the operator. Pinching the saw chain along the top of the guide bar may push the guide bar rapidly back towards the operator. Either of these reactions may cause you to lose control of the saw which could result in serious personal injury.

Do not rely exclusively on the safety devices built into your saw. As a chain saw user you should take several steps to keep cutting jobs free from accident or injury.

(1) With a basic understanding of kickback you can reduce or eliminate the element of surprise. Sudden surprise contributes to accidents.

(2) Keep a good grip on the saw with both hands, the right hand on the rear handle, and the left hand on the front handle, when the engine is running. Use a firm grip with thumbs and fingers encircling the chain saw handles. A firm grip will help you reduce kickback and maintain control of the saw. Don’t let go.

(3) Make certain that the area in which you’re cutting is free from obstructions. Do not let the nose of the guide bar contact a log, branch, or any other obstruction which could be hit while you are operating the saw.

(4) Cut at high engine speeds.

(5) Do not overreach or cut above shoulder height.

(6) Follow manufacturers sharpening and maintenance instructions for saw chain.

(7) Only use replacement bars and chains specified by the manufacturer or the equivalent.

(1) With a basic understanding of kickback you can reduce or eliminate the element of surprise. Sudden surprise contributes to accidents.

(2) Keep a good grip on the saw with both hands, the right hand on the rear handle, and the left hand on the front handle, when the engine is running. Use a firm grip with thumbs and fingers encircling the chain saw handles. A firm grip will help you reduce kickback and maintain control of the saw. Don’t let go.

(3) Make certain that the area in which you’re cutting is free from obstructions. Do not let the nose of the guide bar contact a log, branch, or any other obstruction which could be hit while you are operating the saw.

(4) Cut at high engine speeds.

(5) Do not overreach or cut above shoulder height.

(6) Follow manufacturers sharpening and maintenance instructions for saw chain.

(7) Only use replacement bars and chains specified by the manufacturer or the equivalent.

(1) Gasoline is very flammable. Avoid smoking or bringing any flame or sparks near fuel. Make sure to stop the engine and allow it cool before refueling the unit. Select outdoor bare ground for fueling and move at least 3m (10ft) away from the fueling point before starting the engine.

(2) The RedMax engines are lubricated by oil specially formulated for air-cooled 2-cycle gasoline engine use. If RedMax oil is not available, use an anti-oxidant added quality oil expressly labeled for air-cooled 2-cycle engine use. (JASO FC GRADE OIL or ISO EGC GRADE)

(3) Do not use BIA or TCW (2-stroke watercooling type) mixed oil.

(2) The RedMax engines are lubricated by oil specially formulated for air-cooled 2-cycle gasoline engine use. If RedMax oil is not available, use an anti-oxidant added quality oil expressly labeled for air-cooled 2-cycle engine use. (JASO FC GRADE OIL or ISO EGC GRADE)

(3) Do not use BIA or TCW (2-stroke watercooling type) mixed oil.

Exhaust emission are controlled by the fundamental engine parameters and components(eq., carburation, ignition timing and port timing) without addition of any major hardware or the introduction of an inert material during combustion.

(1) Put a clear indication on the outside of the container to avoid mixing up with gasoline or other containers.

(2) Indicate the contents on outside of container for easy identification.

(1) Put a clear indication on the outside of the container to avoid mixing up with gasoline or other containers.

(2) Indicate the contents on outside of container for easy identification.

1. Untwist and remove the fuel cap. Rest the cap on a dustless place.

2. Put fuel into the fuel tank to 80% of the full capacit.

3. Fasten the fuel cap securely and wipe up any fuel spillage around the unit.

4. Select bare ground for fueling.

5. Move at least 10feet (3meters) away from the fueling point before starting the engine.

6. Stop the engine before refueling the unit. At that time, be sure to sufficiently agitate the mixed gasoline in the container.

2. Put fuel into the fuel tank to 80% of the full capacit.

3. Fasten the fuel cap securely and wipe up any fuel spillage around the unit.

4. Select bare ground for fueling.

5. Move at least 10feet (3meters) away from the fueling point before starting the engine.

6. Stop the engine before refueling the unit. At that time, be sure to sufficiently agitate the mixed gasoline in the container.

FUEL WITH NO OIL(RAW GASOLINE) –It will cause severe damage to the internal engine parts very quickly.

GASOHOL – It can cause deterioration of rubber and/or plastic parts and disruption of engine lubrication.

• These engines are certified to operate on unleaded gasoline.

• Make sure to use gasoline with a minimum octane number of 89 RON (USA/Canada: 87AL)

• If you use a gasoline of a lower octane value than prescribed, there is a danger that the engine temperature may rise and an engine problem such as piston seizing may consequently occur.

• Unleaded gasoline is recommended to reduce the contamination of the air for the sake of your health and the environment.

• Poor quality gasolines or oils may damage sealing rings, fuel lines or fuel tank of the engine.

GASOHOL – It can cause deterioration of rubber and/or plastic parts and disruption of engine lubrication.

• These engines are certified to operate on unleaded gasoline.

• Make sure to use gasoline with a minimum octane number of 89 RON (USA/Canada: 87AL)

• If you use a gasoline of a lower octane value than prescribed, there is a danger that the engine temperature may rise and an engine problem such as piston seizing may consequently occur.

• Unleaded gasoline is recommended to reduce the contamination of the air for the sake of your health and the environment.

• Poor quality gasolines or oils may damage sealing rings, fuel lines or fuel tank of the engine.

Pay attention to agitation

(1) Measure out the quantities of gasoline and oil to be mixed.

(2) Put some of the gasoline into a clean, approved fuel container.

(3) Pour in all of the oil and agitate well.

(4) Pour In the rest of gasoline and agitate again for at least one minute. As some oils may be difficult to agitate depending on oil ingredients, sufficient agitation is necessary for the engine to last long. Be careful that, if the agitation is insufficient, there is an increased danger of early piston seizing due to abnormally lean mixture.

(5) OIL FOR 4-CYCLE ENGINE USE – It can cause spark plug fouling, exhaust port blocking, or piston ring sticking.

(6) Mixed fuels which have been left unused for a period of one month or more may clog the carburetor and result in the engine failing to operate properly.

(1) Measure out the quantities of gasoline and oil to be mixed.

(2) Put some of the gasoline into a clean, approved fuel container.

(3) Pour in all of the oil and agitate well.

(4) Pour In the rest of gasoline and agitate again for at least one minute. As some oils may be difficult to agitate depending on oil ingredients, sufficient agitation is necessary for the engine to last long. Be careful that, if the agitation is insufficient, there is an increased danger of early piston seizing due to abnormally lean mixture.

(5) OIL FOR 4-CYCLE ENGINE USE – It can cause spark plug fouling, exhaust port blocking, or piston ring sticking.

(6) Mixed fuels which have been left unused for a period of one month or more may clog the carburetor and result in the engine failing to operate properly.

Maintenance, replacement, or repair of the emission control device and systems may be performed by any non-road engine repair establishment or individual. Before cleaning, inspecting or repairing your unit, make sure that engine has stopped and is cool. Disconnect the spark plug to prevent accidental starting.

1. Air Filter

Dust on the cleaner surface can be removed by tapping a corner of the cleaner against a hard surface. To clean dirt in the meshes, split the cleaner into halves and brush in gasoline. When using compressed air, blow from the inside. To assemble the cleaner halves, press the rim until it clicks. When installing the main filter, make sure that the grooves on the filter edge are correctly fit with the projections on the cylinder cover.

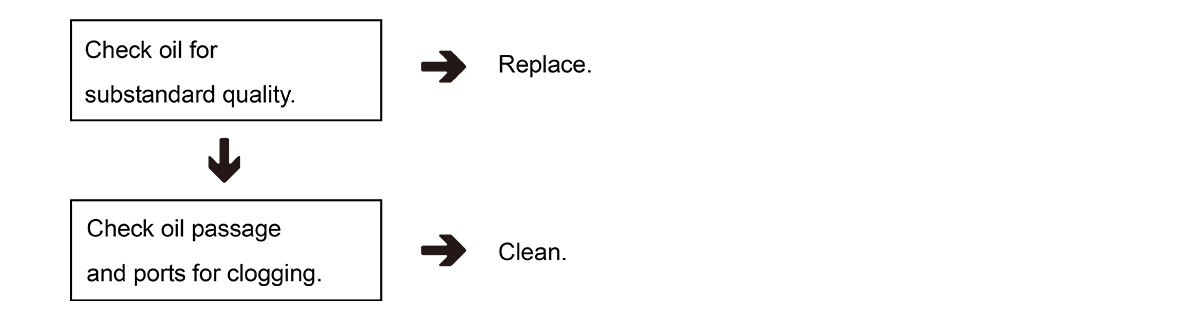

2. Oiling Port

Dismount the guide bar and check the oiling port for clogging.

3. Guide Bar

When the guide bar is dismounted, remove sawdust in the bar groove and the oiling port. Grease the nose sprocket from the feeding port on the tip of the bar.

4. Others

Check for fuel leakage and loose fastenings and damage to major parts, especially handle joints and guide bar mounting. If any defects are found, make sure to have them repaired before operating again.

1. Air Filter

Dust on the cleaner surface can be removed by tapping a corner of the cleaner against a hard surface. To clean dirt in the meshes, split the cleaner into halves and brush in gasoline. When using compressed air, blow from the inside. To assemble the cleaner halves, press the rim until it clicks. When installing the main filter, make sure that the grooves on the filter edge are correctly fit with the projections on the cylinder cover.

2. Oiling Port

Dismount the guide bar and check the oiling port for clogging.

3. Guide Bar

When the guide bar is dismounted, remove sawdust in the bar groove and the oiling port. Grease the nose sprocket from the feeding port on the tip of the bar.

4. Others

Check for fuel leakage and loose fastenings and damage to major parts, especially handle joints and guide bar mounting. If any defects are found, make sure to have them repaired before operating again.

1. Cylinder Fins

Dust clogging between the cylinder fins will cause overheating of the engine. Periodically check and clean the cylinder fins after removing the air cleaner and the cylinder cover. When installing the cylinder cover, make sure that switch wires and grommets are positioned correctly in place. Be sure to block the air intake hole.

2. Fuel Filter

• After removing the filter, use a pinch to hold the end of the suction pipe.

• When assembling the filter, take care not to allow filter fibers or dust inside the suction pipe.

3. Oil Tank

With a wire hook, take out the oil filter through the filler port and clean in gasoline. When putting the filter back into the tank, make sure that it comes to the front right corner. Also clean off dirt in the t

4. Spark Plug

Clean the electrodes with a wire brush and reset the gap to 0.65 mm as necessary.

5. Sprocket

Check for cracks and for excessive wear interfering with the chain drive. If the wearing is found obviously, replace it with a new one. Never fit a new chain on a worn sprocket, or a worn chain on a new sprocket.

6. Front And Rear Dampers

Replace if adhered part is peeled or crack is observed on the rubber part.

Dust clogging between the cylinder fins will cause overheating of the engine. Periodically check and clean the cylinder fins after removing the air cleaner and the cylinder cover. When installing the cylinder cover, make sure that switch wires and grommets are positioned correctly in place. Be sure to block the air intake hole.

2. Fuel Filter

• After removing the filter, use a pinch to hold the end of the suction pipe.

• When assembling the filter, take care not to allow filter fibers or dust inside the suction pipe.

3. Oil Tank

With a wire hook, take out the oil filter through the filler port and clean in gasoline. When putting the filter back into the tank, make sure that it comes to the front right corner. Also clean off dirt in the t

4. Spark Plug

Clean the electrodes with a wire brush and reset the gap to 0.65 mm as necessary.

5. Sprocket

Check for cracks and for excessive wear interfering with the chain drive. If the wearing is found obviously, replace it with a new one. Never fit a new chain on a worn sprocket, or a worn chain on a new sprocket.

6. Front And Rear Dampers

Replace if adhered part is peeled or crack is observed on the rubber part.

When your unit seems to need further service, please consult with our service shop in your area.

1. Empty the fuel tank and run the engine out of fuel.

2. Empty the oil tank.

3. Clean the entire unit.

4. Store the unit in a dry place out of the reach of children.

2. Empty the oil tank.

3. Clean the entire unit.

4. Store the unit in a dry place out of the reach of children.